Micro Fulfillment Centre: The Small Logistics Solution With Big Benefits

In an e-commerce industry where bigger is better, going micro is surprisingly effective at helping retailers to scale up.

Picture this: It's the year 2050. You're in a bustling city surrounded by towering skyscrapers, yet you spot a small, unassuming building tucked away alongside them. It has a sign saying ‘ABC micro fulfillment centre’.

Curious, you walk in and ask to look around. Within moments, mobile robots whizz by carrying packages to pack onto waiting drones; behind them automated systems pick items off shelves and place them on conveyor belts.

Welcome to the world of micro fulfillment centres (MFC) where technology meets logistics to provide maximum speed and efficiency in order fulfillment. In 2050, the super-advanced e-commerce industry offers same-day delivery as the bare minimum. As such, micro warehousing is now standard for online retailers.

This may sound slightly futuristic, but we don’t have to wait 25 years for it to happen.

Micro fulfillment centres are already here. Mobilised by the spike in customer demand for online orders during the pandemic, large home delivery firms have set about building micro-storage facilities to keep their supply chain flowing.

In the UAE, Carrefour launched a fully automated micro fulfillment centre, with all orders prepared within five minutes, slashing the average time by 50% and allowing up to 200 orders to be sent out every hour.

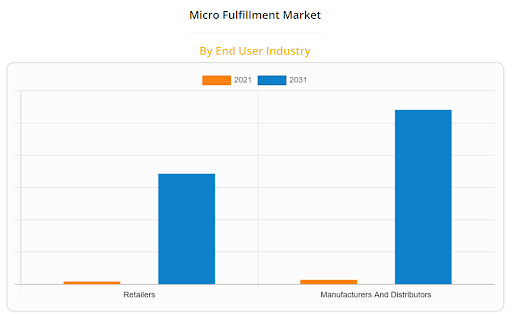

Such developments are part of a wider picture in the global micro fulfillment industry, predicted to grow at a rate of almost 45% CAGR until 2031, giving it a value of $88.3 billion, according to figures from Allied Market Research.

Source: Allied Market Research

So what does this mean for businesses in the UAE that are looking for innovative e-commerce solutions that slash delivery times? Could a micro fulfillment strategy be one of them?

This article aims to find out.

Sign up to swftbox in just five minutes to find out how integrated MFCs can play a key role in an upgraded delivery process that keeps your customers smiling.

What are micro fulfillment centres?

10,000 square feet may sound like a lot, but in warehousing terms it’s tiny. To put it into context, picture two basketball courts side-by-side. This is the typical size of a micro fulfillment centre, a small warehouse facility, or dark store, where online brands can hold their products before shipping. MFCs are strategically placed in densely populated urban locations, often packed between larger structures, as mentioned in the futuristic example mentioned above. They allow retailers to store items closer to their customers, as opposed to traditional warehouses that tend to be placed in much larger plots of land on the edge of town.

Sometimes businesses build MFCs into an existing site, such as a grocery store, which saves building or converting a site from scratch. For most online retailers, though, the easiest way to access them is via a fulfillment centre partner with MFC access.

The compact nature of an MFC is partly thanks to its use of automated systems, which optimise space usage and reduce the need for human labour. Instead, they’re designed to carry out much faster fulfillment than in distribution centres of old.

Large firms like Walmart, and Amazon distribute these small fulfillment hubs based on heat maps within a city to ensure they have sufficient coverage for high-demand areas. This way, they reduce shipping mileage and costs and are able to scale up and down when necessary.

Such sophisticated fulfillment operations may be out of the reach of most retailers, but MFCs still offer smaller companies several advantages over traditional order fulfillment.

What’s the difference between traditional order fulfillment and MFC?

Although they have similar objectives, MFCs have a different approach to carrying out fulfillment operations compared to their larger counterparts.

First is the heightened use of smart technology that makes much quicker processing possible. MFCs rely heavily on automation to accelerate warehouse tasks. They use mobile robots and conveyor belts for fetching and carrying, and automated inventory management to update and replenish stock levels. Because MFCs stock a smaller selection of products, they also focus on high-volume stock-keeping units (SKUs) that they can fulfil quickly and efficiently.

MFCs also tend to be more adaptable and scalable with businesses able to adjust their output without adding to the physical size of the facility. Their speed and flexibility make them ideal for omni-channel distribution with in-store pickup and same-day delivery made more possible. Not to mention more chances of cash on delivery thanks to more efficient drop-off routes.

Challenges to consider

Yet for all their positives, MFCs also have a few comparative disadvantages. An MFC’s heavier investment in automation technology means there may be a higher entry cost for a small-scale retailer wishing to use them. That’s not to mention maintenance expenses for tech malfunctions. Businesses that stock a wide variety of orders may find their options restricted at an MFC, which is designed to focus on fast-moving SKUs with a narrower range of goods. A store owner may find that they need several MFCs to cover their product selection, which may mount up to a significant investment.

There’s also a chance that an overreliance on urban MFCs may alienate customers in more rural areas as goods struggle in the traffic outflow when leaving the city. This is particularly true for sellers of home improvement and car-related goods as consumers out of town tend to own larger properties and drive more than urban residents. On balance, however, many online retailers are finding a micro fulfillment strategy to be an essential part of a faster delivery process.

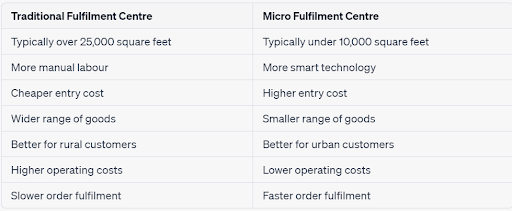

Traditional fulfillment centres vs micro fulfillment solutions

What’s an example of a micro fulfillment centre process?

Talking of how MFCs contribute to a faster fulfillment process is one thing, but what does one look like from the inside, and how exactly does it dial up speed and efficiency? Well, we can answer these questions by looking in detail at several real-world examples and pinpointing the various cogs in the micro fulfillment wheel.

Here’s a step-by-step process.

A customer’s order triggers the MFC’s inventory management system, which is integrated into various online platforms and mobile apps.

The system uses robotics to locate and retrieve the products from storage.

Conveyor belts, sorting machines, and robotic arms arrange and package the goods automatically.

The packaged items pass through system-operated quality control checks to make sure they’re in top condition.

Automated labels and documentation are attached to the products, which are put out for delivery.

A team of human workers, sometimes assisted by mobile robots, either load the goods onto delivery vehicles or send them to a designated customer pick-up area.

This operational system is often inter-connected with internet-of-things (IoT) devices so that human users at each stage of the supply chain can have an overview of the entire process and highlight any bottlenecks that occur along the way.

Despite their small size, it’s possible for MFCs to handle thousands of orders per day thanks to this digitised and streamlined process. Combined with their strategic location, this can make them an extremely potent weapon in the battle for fast deliveries.

Their compact nature means they can even be added to existing retail spaces, such as the side of a brick-and-mortar store, with the retailer benefiting from on-site fulfillment to go with their physical sales.

How can e-commerce retailers use micro fulfillment centres to benefit their business?

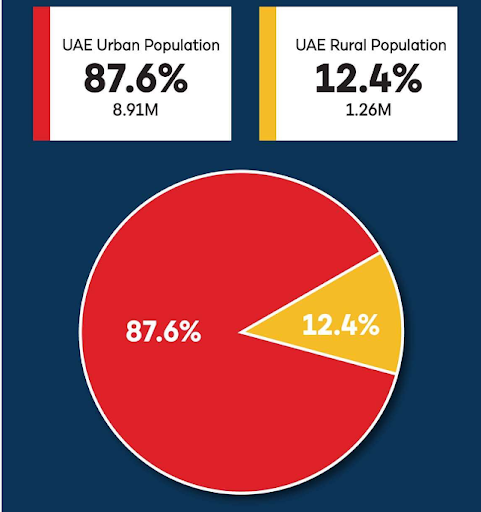

In an online shopping industry obsessed with speed, many retailers are looking for ways to get a competitive advantage over their rivals. Micro fulfillment centres have the potential to be one of those, particularly in the UAE where an overwhelming percentage of the population – 87.6% according to research firm Global Media Insight – live in the urban areas that MFCs cater to.

The UAE’s urban/rural demographics

Source: Global Media Insights

From quicker deliveries to happier customers, here’s how MFCs can benefit an ambitious online retailer in today’s market.

Faster order fulfillment and last-mile delivery

Automation is the grease that oils the wheels of accelerated order fulfillment and MFCs use lots of it. The time between the customer clicking the ‘buy’ button and the product being placed in the hands of a delivery courier is reduced to minutes as the automated processes outlined above kick into place. This makes for a faster delivery process as products are ready and waiting for couriers when they arrive, often just before the cut-off time. The delivery vehicle then covers less distance thanks to the MFC’s strategic location. There’s less chance of taking the wrong route or hitting a traffic jam, and the densely populated area means the courier is able to include more drop-offs in his or her route.

Improved customer experience

It’s the golden rule of deliveries: the customer who gets their purchase on time is a happy customer. The proximity of an MFC means they’re much more likely to get their e-commerce order on the same day rather than the next day or in two days’ time. A smaller distance means a lower chance of damaged goods the inevitable complaint that follows. What’s more, a happy customer is more likely to use your service again or recommend a service to a friend, and everyone knows what that leads to.

Increased sales

Every business owner knows that repeat customers and referrals boost sales, but MFCs also help scale up operations should a retailer receive a surge in orders. Micro fulfillment automation makes it possible to deal with larger delivery volumes with less manual labour and fewer errors as users can adjust their output in real time.

Lower operating costs

One of the most attractive elements of using an MFC is that it has the potential to dramatically reduce operating costs. Smaller real estate means lower overheads, automation reduces the reliance on manual labour, while a shorter last-mile delivery journey saves on fuel and driver costs. Businesses that are able to incorporate MFCs into their existing retail stores can make a dramatic impact on their ongoings as it saves them having to invest in a separate distribution centre. In the United States, Walmart reported a 40% year-over-year growth in this metric, while retail depot Target reported that 95% of its total online orders were processed in existing stores in the second quarter of 2022. Retailers deal with their online orders directly from the same space as their in-store operations, with customers also having the option of choosing a store pick-up option, if necessary.

An MFC-driven future

Fast order processing is already at the heart of the digital logistics industry. Online retailers eager to meet the challenges of same-day delivery are finding that micro fulfillment centres are a useful mechanism, which explains their growing adoption across the world. As the investment in MFC continues to grow, the technology that powers them will become more sophisticated. Artificial intelligence (AI) will assist in processing orders at an even faster pace than now, maintaining sky-high levels of accuracy. The use of mobile robots and automation will continue to increase, paving the way for greater efficiency and flexibility. This is good news for small retailers.

MFCs are more accessible than larger sites and, when used correctly, may help stores compete with larger rivals by getting smart with their fulfillment rather than just throwing money at the problem. They provide a cost-effective solution to scaling up operations without having to invest in large warehouse space. They help keep customers happy by making an omnichannel distribution system more likely. In a world where quickness wins the race over style, MFCs may just end up being the weapon that small e-commerce stores didn’t know they needed.

Ready to speed up your fulfillment process? Sign up to swftbox in just five minutes to tap into our flexible network of automated MFCs and quick courier services that will supercharge your deliveries.